Insider Tips for Getting the Most Out of litho printing

Insider Tips for Getting the Most Out of litho printing

Blog Article

A Comprehensive Overview to Understanding Litho Printing Strategies

The world of litho printing, a strategy originating from the late 18th century, is an interesting blend of background, art, technology and scientific research. Remain with us as we trip into the exciting world of litho printing.

The Historic Development of Litho Printing

The historical trajectory of litho printing, a critical advancement in the world of communication, is a captivating tale of human ingenuity. Birthed in the late 18th century by Alois Senefelder, this strategy was originally an affordable approach of publishing staged works. Lithography, stemmed from the Greek words for 'stone' and 'to compose', utilized a smooth rock surface to transfer photos onto paper. The process developed with the introduction of the rotary press, which significantly raised performance (litho printing). In the 20th century, the innovation of offset lithography reinvented the industry, enabling mass manufacturing of high-grade prints. Each stage of litho printing's advancement showcases humankind's relentless quest of performance and top quality in visual communication.

Decoding the Science Behind Litho Printing Inks

Moving on in the exploration of litho printing techniques, the focus now shifts to the science behind litho printing inks. The composition of these inks, their drying out procedure, and color mixing methods form the backbone of this complicated art type. Understanding these components is critical to mastering the craft and achieving the desired print outcomes.

Structure of Litho Inks

In lithographic printing, the fundamental duty of litho inks can not be overstated. The structure of litho inks varies relying on its purpose, but usually, they consist of 2 major components - lorries and pigments. Pigments, the color-providing components, are carefully ground fragments suspended in the automobile, a fluid that lugs the pigment onto the printing surface. The car is a complex blend of solvents, resins, and oils, which influence the ink's drying out time, attachment, and gloss. Additionally, different ingredients are present to boost particular homes like flow, drying out, and resistance to ecological impacts. Each component plays an essential part in the last print's quality, making the accurate formula of litho inks an elaborate scientific research.

Ink Drying Refine

From the composition of litho inks, attention transforms to the interesting procedure of ink drying out. The drying procedure is essential, as it affects the final print's high quality and long life. 2 primary methods are used in litho printing: oxidative drying and absorption. Oxidative drying out entails the ink reacting with oxygen in the air to form a tough, completely dry film. This technique offers a long lasting coating, however can be slower compared to absorption. Absorption, on the various other hand, entails the ink leaking into the paper fibers, which is a quicker process yet can lead to much less vibrant shades. The selection in between these approaches is dependent upon variables such as print speed requirements, the paper type used, and the wanted surface.

Shade Mixing Strategies

While the drying out procedure plays a key duty in litho printing, the science of shade mixing techniques holds equal significance. This is a complicated process that includes the mindful blending of primaries: cyan, magenta, and yellow, in varying percentages to achieve a wide selection of colors. The addition of black ink, referred to as 'vital', aids in controling the strength and depth of the colors. The scientific research behind litho printing inks likewise takes into account the transparency of the ink, which affects how shades overlay and mix. To attain an effective color mix, print specialists should likewise understand the details of ink habits, shade theory, and the physical residential or commercial properties of the substratum on which the ink is applied.

The Art and Design Aspects in Litho Printing

Litho printing breathes life into art and design through its special components. The process includes producing a photo on a lithographic limestone plate or metal plate with a smooth surface area. The photo is then published onto a medium, generally paper, by moving the ink from home plate. What sets litho publishing apart is its capacity to replicate intricate layouts with high integrity, making the output practically similar to the initial art work. This is attained through making use of different line strategies such as stippling, hatching, and cross-hatching, which permit for a variety of tonal impacts. Additionally, litho printing fits a selection of colors, enabling artists to create vivid and vibrant prints. This combination of accuracy and convenience makes litho printing a favored choice for many artists and developers.

Modern Applications of Litho Printing Techniques

Litho printing methods have found substantial usage in the modern business field. Its influence and relevance remain to expand with the introduction of brand-new technologies and technologies in the area. This section will check out these modern applications and the transformative role they play in the printing sector.

Commercial Litho Printing Uses

Litho printing remains an important part of the commercial market. High-volume printing tasks, such as the manufacturing of books, papers, and product packaging, rely on litho printing for its capacity to supply exceptional picture why not look here high quality and price performance. Litho printing additionally supplies a broad color range, superior to that of digital printing.

Developments in Litho Printing

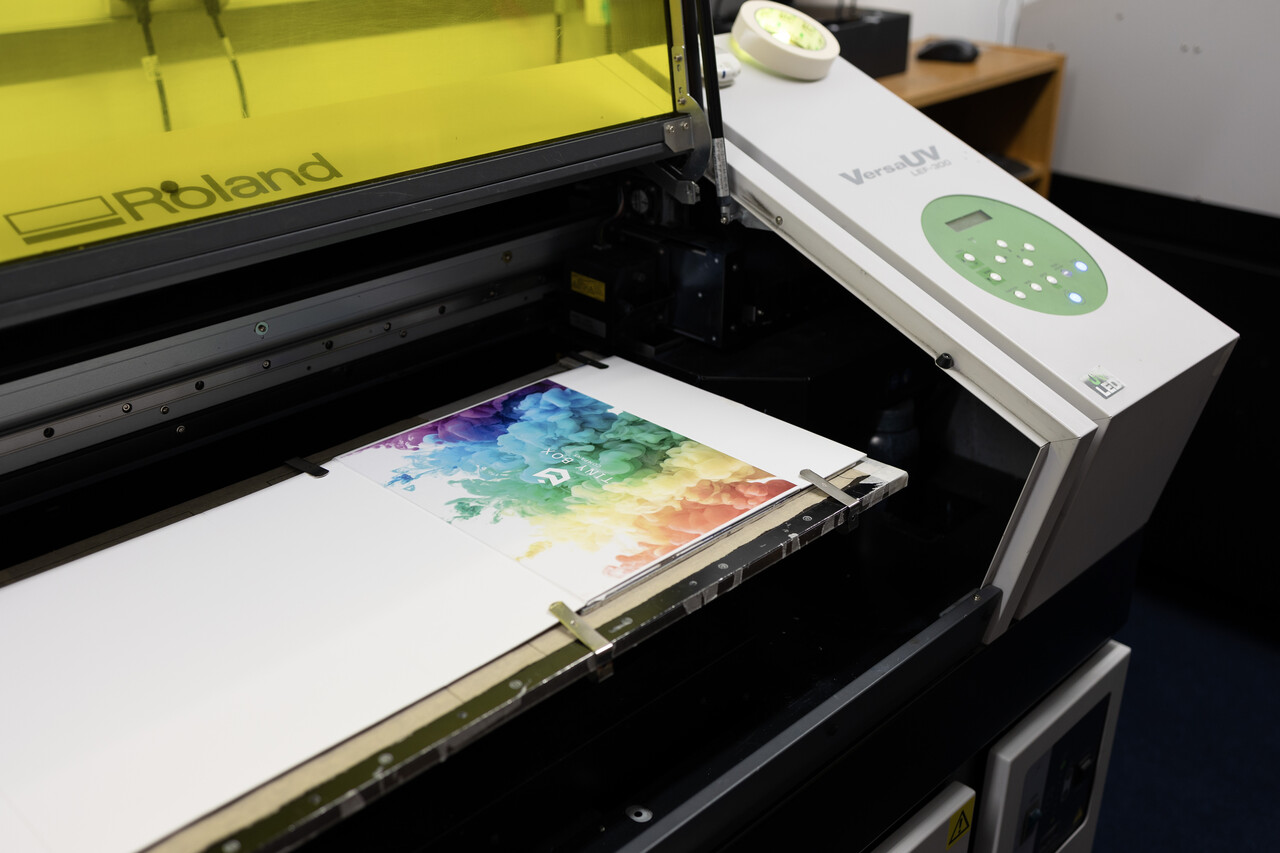

Pressing the limits of traditional techniques, modern advancements have actually sustained a host of technologies in litho printing. These developments have not only improved the quality and efficiency of litho prints yet additionally increased its application scope. One popular advancement is electronic litho printing, which combines the virtues of electronic innovation with here are the findings litho's top notch output. This hybrid version offers faster setup times, reduced waste, and enables on-demand printing. One more significant development is the introduction of eco-friendly inks. These inks, made from veggie or soy-based solutions, have actually dramatically decreased the industry's ecological effect. litho printing. In addition, the growth of advanced plate technology has structured the printing procedure, resulting in sharper photos and enhanced color integrity. These advancements emphasize the long-lasting relevance of litho printing in the modern world.

Discovering the Refine of Litho Printing: Detailed

Obstacles and Solutions in Contemporary Litho Printing

Despite the accuracy and tradition that litho printing proudly upholds, it is not without its collection of modern difficulties. Digital litho printing enables for economical short runs and simple modification, attending to the issue of variable information. Thus, while there are obstacles, the litho printing sector is proactively adapting to meet them head-on, guaranteeing its relevance in the future.

Verdict

In verdict, litho printing, with its abundant history and scientific ins and outs, holds a substantial place in the print sector. The future of litho printing hinges on its capability to adjust to these transforming needs, attesting its enduring worth in a developing market.

Report this page